Production Overview

Reliable quality, built with rugged materials and skilled craftsmanship.

From raw materials to final packaging, every step in our production process is carefully controlled to ensure top quality, reliability, and on-time delivery—so you can trust your orders are in expert hands.

Battery Pack Production Process

Battery Cell

High-quality EV-grade battery cells delivered in bulk, ensuring premium performance and reliability.

Parameter Testing

Each cell undergoes rigorous parameter testing to guarantee compliance with strict operational standards.

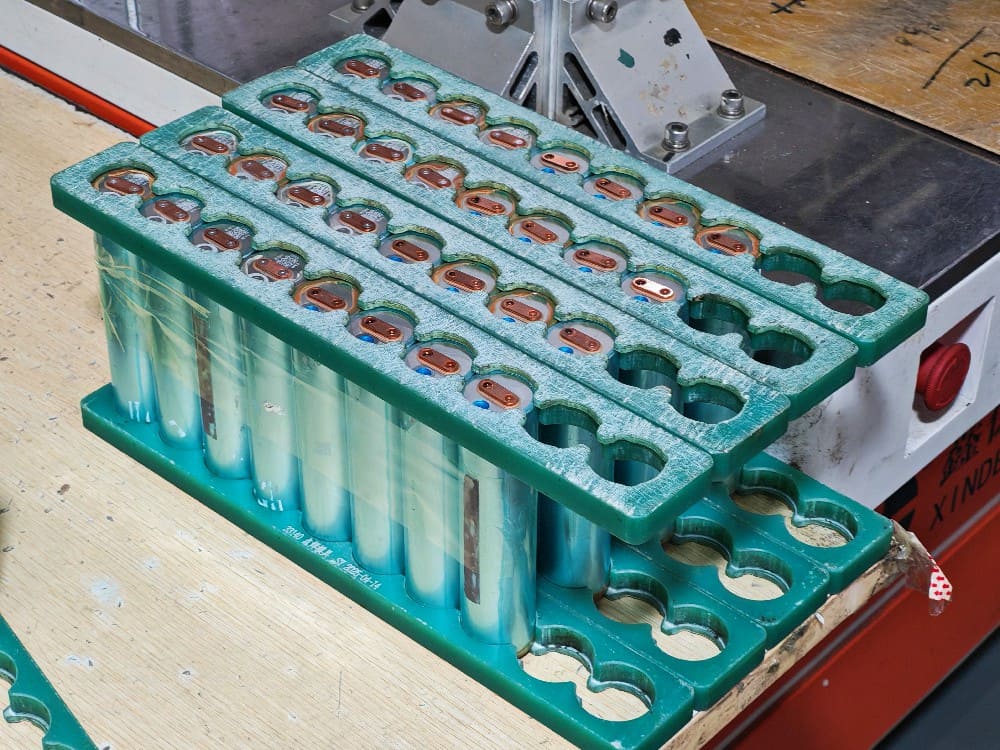

Insert in Mold

Cells are precisely placed into molds and secured with durable tape for stable alignment.

Insert copper conductor

High-conductivity copper strips are affixed to electrodes, enhancing electrical efficiency and durability.

Laser Welding

Precision laser welding bonds copper strips to each cell’s electrodes, ensuring optimal circuit continuity.

Bond with adhesive

Industrial-grade adhesive is applied between cells for structural integrity and vibration resistance.

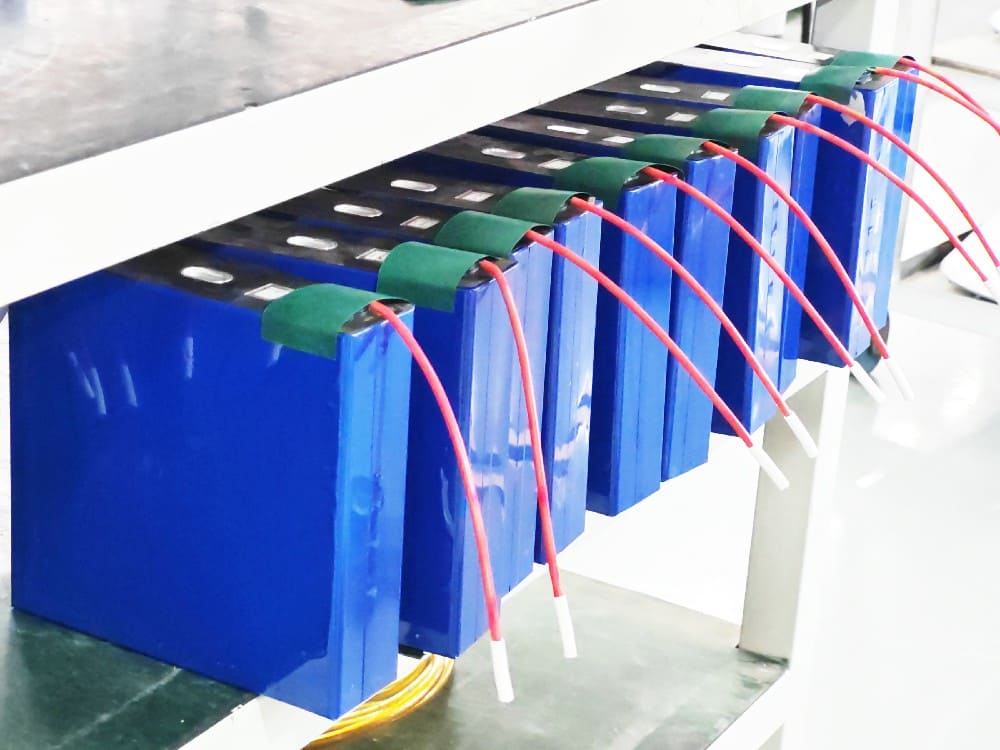

Heat-shrink wrap

The assembled battery pack is tightly sealed with heat-shrink film for reinforced stability and protection.

Battery pack ready

Finished packs are loaded onto trolleys, QC-approved and prepared for deployment.

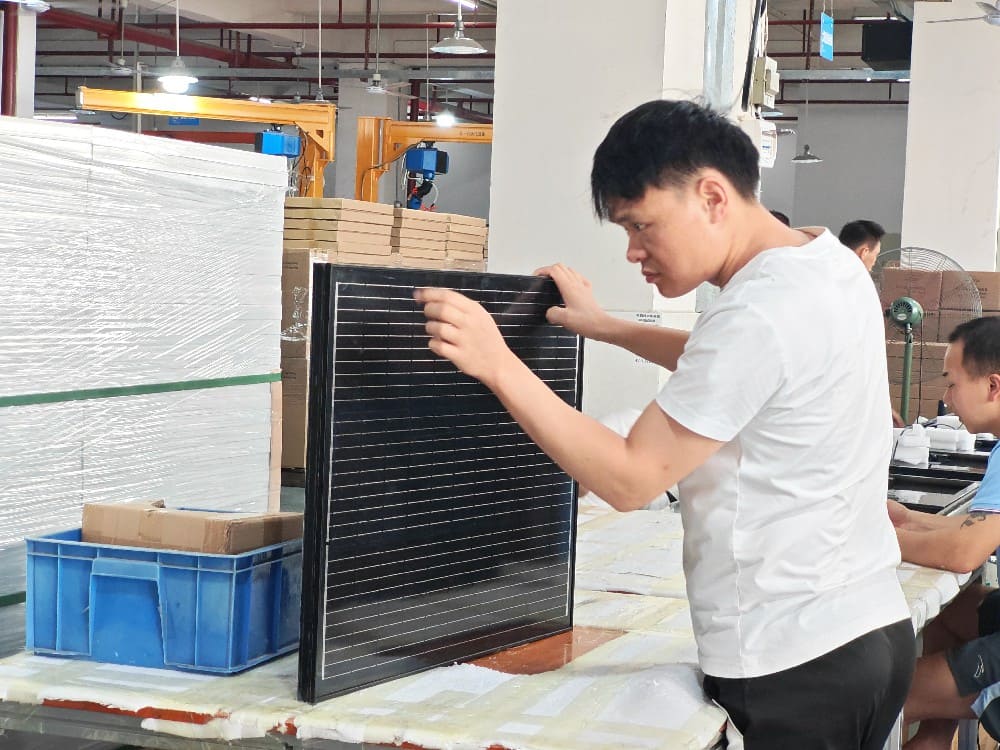

Solar Panel Production Process

Visual Inspection

Ensures flawless appearance and durability.

Wiring & Connection

Secure, high-efficiency electrical contact.

Functional Test

Validates power output and reliability.

Flatness Check

Guarantees seamless installation and operation.

Split-Mount Solar Street Light Production Process

Install Connector

IP67-rated threaded connectors with silicone sealing.

Connect Cable

Secure and stable power input.

Apply Adhesive

Industrial adhesive ensures reliable and durable bonding.

Fixing Bracket

Reinforced metal frame for extra stability.

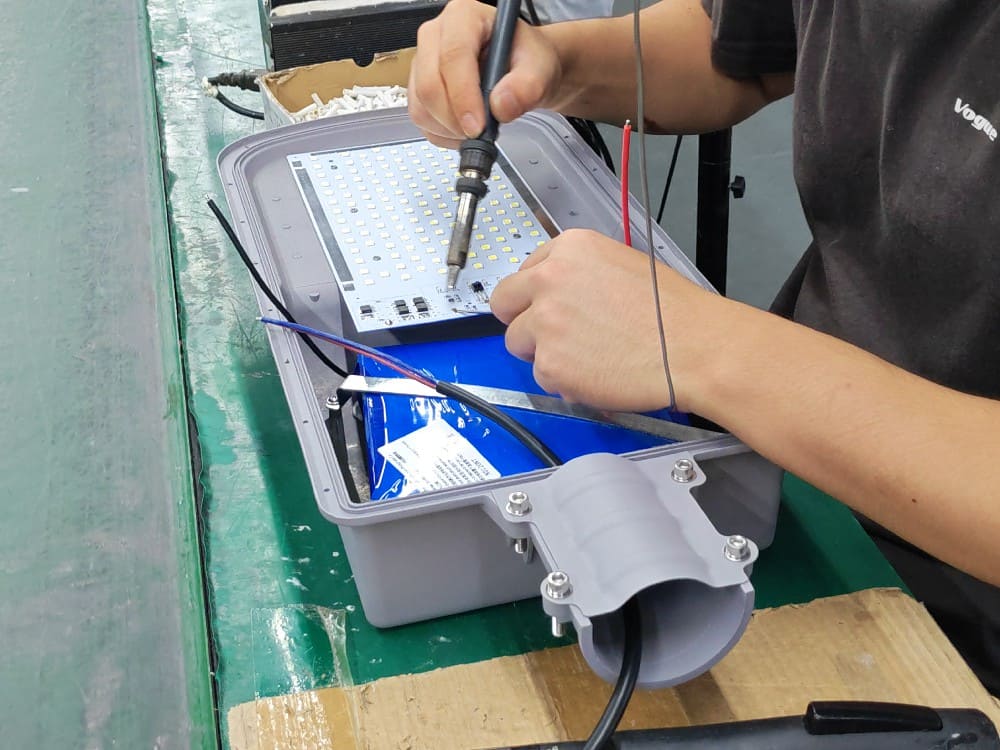

Solder LED Board

Skilled staff perform lead-free soldering.

Function Test

Verifies instant response and correct operation.

Fit Waterproof Gasket

Silicone gasket to enhance water and dust resistance.

Attach Light Cover

Impact-resistant lens for longevity and clarity

All-in-One Solar Street Light Production Process

Frame Assembly

High-strength aluminum alloy frame for enhanced durability and optimized heat dissipation.

Solar Panel Installation

High-efficiency monocrystalline solar panel for maximum sunlight absorption.

Waterproof Sealing

Industrial-grade waterproof sealant between solar panel and frame to ensure IP protection.

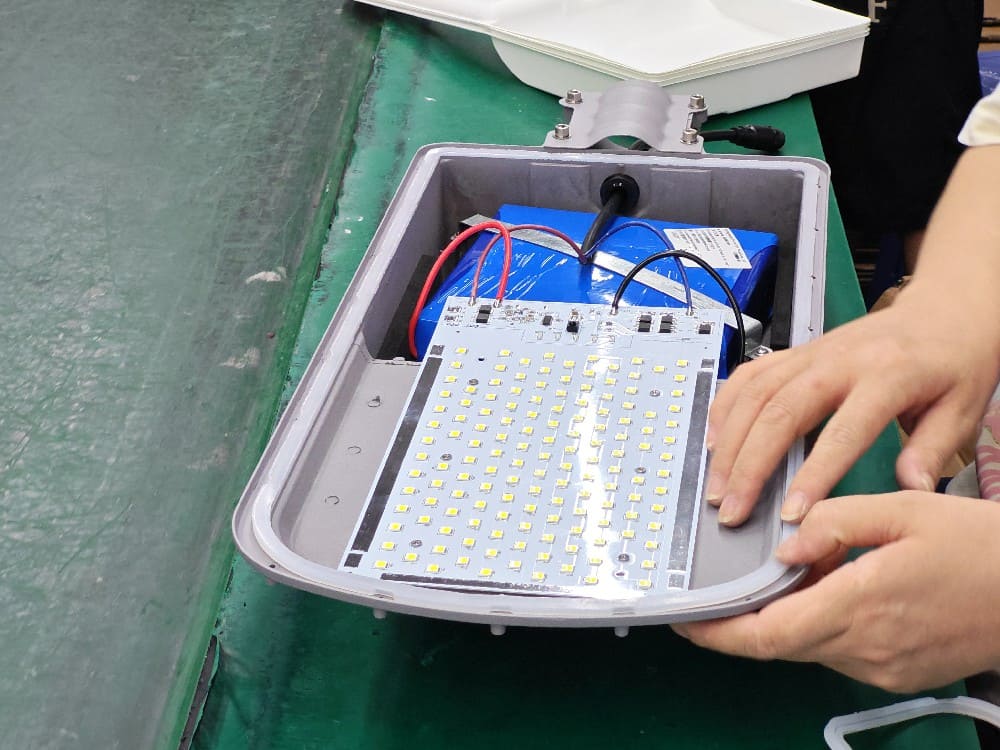

Install Battery & Controller

Lithium battery pack and smart charge controller installed for stable power management.

Structural Locking

Internal metal bracket reinforces lamp housing, enhancing structural rigidity and shock resistance.

LED Board Installation

High-lumen LED modules installed and precisely wired for optimal brightness and efficiency.

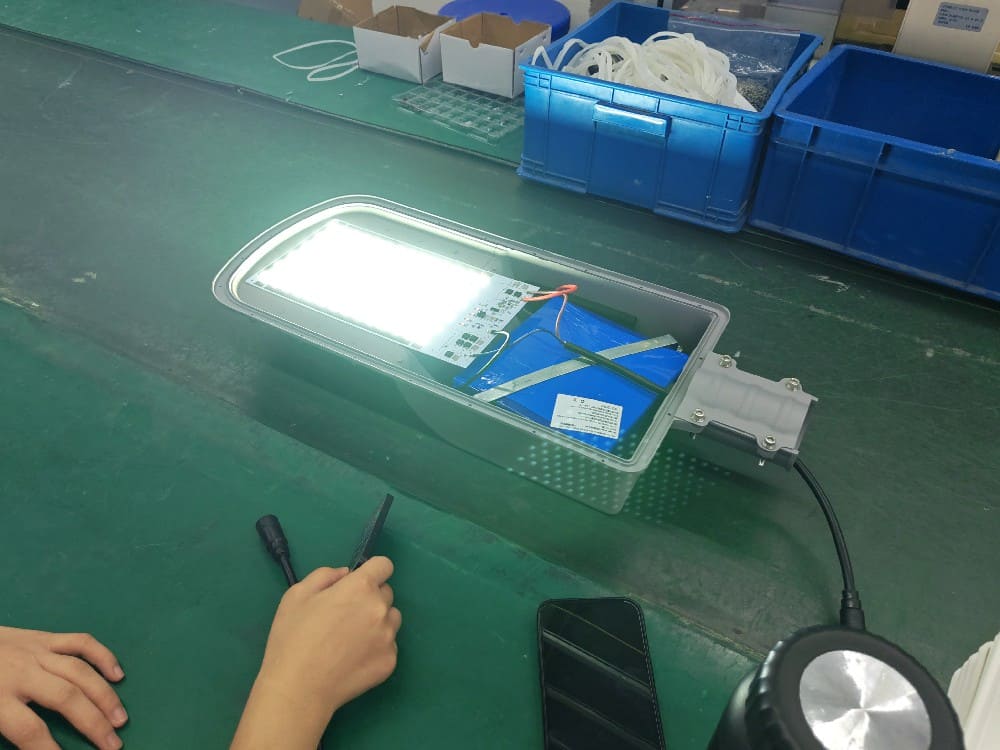

Functional Testing

Each unit undergoes power-on testing to verify LED operation and remote control functionality.

Sensor Mode Setup

Pairing test, ensuring the receiver correctly syncs with remote control for all functional commands.